Our company continuously strives to develop its resources through both internal funding and grant opportunities, while keeping pace with technological challenges and meeting the needs of our clients.

As the initial step of the workflow, precise preparation and cutting of incoming raw materials is essential. Profile materials are processed using a band saw, while sheets are prepared for further processing with a CNC 5-axis fine plasma cutter and flame cutting equipment.

After cutting, our highly skilled and experienced fitters assemble the workpieces on tables of various sizes according to the technical drawings.

Welding is carried out by our certified welders using high-performance CO impulse welding machines.

We carry out the processes on various CNC and conventional machining equipment. We can machine workpieces up to 3.5 meters in length, and we also operate lathes of various sizes, with a maximum length capacity of 3000 mm.

With our available machinery, we guarantee the accurate and precise execution of the manufactured steel structures.

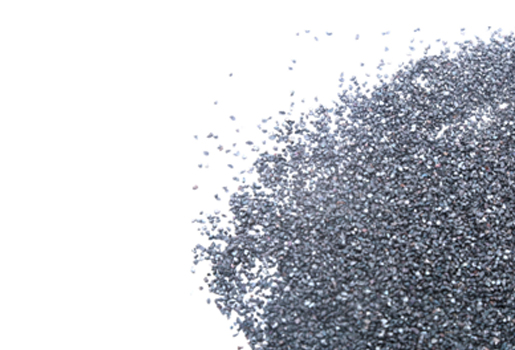

As the final step of the process, we perform surface treatment by abrasive blasting. We operate our own blasting workshop and equipment, ensuring corrosion-free preparation for any subsequent surface finishing.

Material handling is an essential part of our workflow, carried out using high-capacity overhead cranes (one 8-ton, two 5-ton, and one 3.2-ton unit), as well as a 3.5-ton forklift operating both inside and outside the workshop.

We consider quality control to be of utmost importance and perform it continuously throughout and at the end of each process.

The high-quality execution of our work would not be possible without our colleagues, who possess outstanding professional knowledge, extensive experience, and qualifications (including mechanical engineers, mechanical technicians, fitters, welders, and machinists).